Best Cooling Tower Designs for Efficient Performance?

cooling towers play a crucial role in many industries. They remove excess heat from processes, ensuring optimal performance. According to a report by the U.S. Department of Energy, efficient cooling towers can reduce energy consumption by up to 30%. This efficiency is vital for industries like power generation and manufacturing.

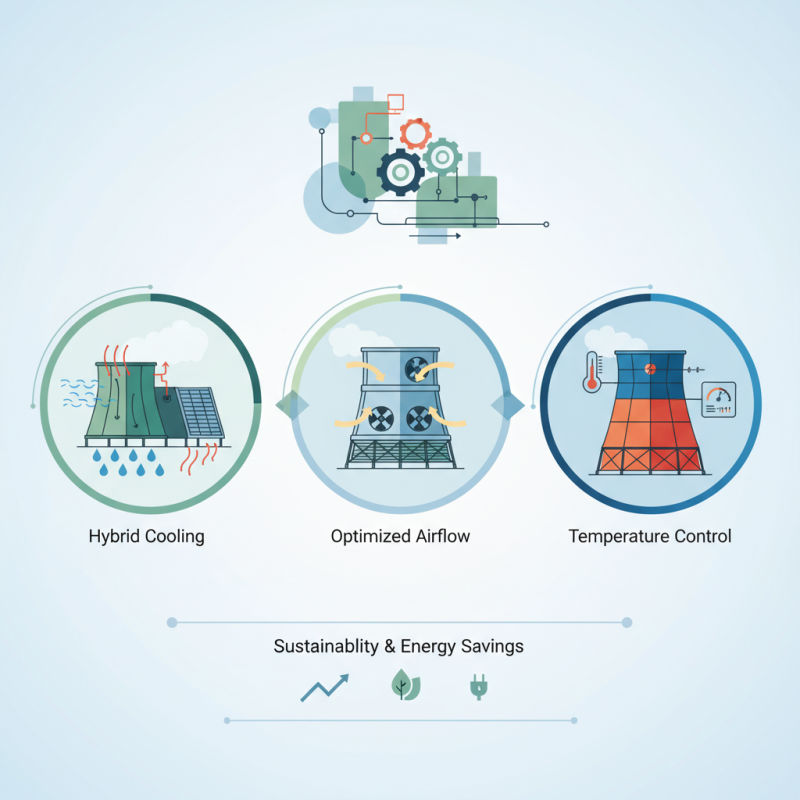

In recent years, innovative designs have emerged. These new cooling towers focus on sustainability and energy savings. For example, hybrid cooling towers combine dry and wet cooling methods. This approach can enhance efficiency while minimizing water usage. However, not all cooling tower designs are created equal. Companies must carefully evaluate their options.

Mistakes in cooling tower design can lead to significant operational issues. Overlooking temperature control and airflow can hinder performance. Therefore, understanding the best practices in cooling tower design is essential. This knowledge will help industries enhance their performance while addressing environmental concerns.

Overview of Cooling Tower Functionality and Importance

Cooling towers serve a critical role in many industrial processes. They dissipate excess heat from machinery, improving efficiency. Understanding how they work is essential for optimizing performance. When water circulates through a cooling tower, it absorbs heat. As the water evaporates, it cools down significantly. This process can reduce temperatures dramatically, benefiting various applications.

Data from industry reports indicate that a well-designed cooling tower can achieve up to a 30% increase in energy efficiency. Proper maintenance and design are crucial. For example, regular cleaning can prevent blockages that hinder airflow. This can lead to substantial energy savings while prolonging the equipment's life.

Tips: Monitor water levels consistently. Imbalanced levels may signify leaks or inefficiencies. Also, invest in high-quality filtration systems. They enhance heat exchange and improve cooling efficiency. Overlooking these aspects can result in increased operational costs and reduced system effectiveness. Evaluate your cooling tower performance regularly to identify potential improvements.

Key Factors in Designing Efficient Cooling Towers

When designing efficient cooling towers, several key factors must be considered. Airflow is crucial for optimal heat exchange. A well-designed cooling tower maximizes airflow, reducing energy consumption. Industry data suggests that improved airflow can lead to a 25% increase in cooling efficiency.

Material choice also influences performance. Durable materials resist corrosion and extend lifespan. For instance, reinforced concrete or corrosion-resistant metals often enhance thermal conductivity. Reports indicate that proper material selection can prevent maintenance costs from rising by up to 30%.

Tower height and the arrangement of fill media play a significant role too. Taller towers can improve cooling capacity, but they might require more energy for water circulation. Balancing height with efficiency is necessary. Unfortunately, many designs overlook this aspect, leading to inefficiencies. Reflections on past projects reveal that slight adjustments can yield significant gains.

Types of Cooling Tower Designs: Pros and Cons

Cooling towers are essential in various industries. They help remove excess heat. Understanding the different designs can enhance efficiency. Here are common types of cooling tower designs and their pros and cons.

Open cooling towers are widely used. They are cost-effective and straightforward to maintain. However, they require regular cleaning to avoid contamination. The evaporation process is efficient, but it can lead to water loss. This may not be sustainable in water-scarce areas.

Closed cooling towers provide a separate water circuit. This design minimizes evaporation and water loss. Yet, they can be more complex. Maintenance can be challenging, especially if cooling loads fluctuate. It's crucial to assess your operational needs carefully before choosing the design. Each type has its specific advantages and drawbacks.

Innovative Materials and Technologies for Enhanced Performance

Innovative materials and technologies are reshaping cooling tower designs to enhance performance. For instance, advanced composite materials offer improved strength and corrosion resistance. Such innovations can increase the lifespan of cooling towers and reduce maintenance costs significantly. According to recent industry reports, the utilization of these materials has led to a 25% reduction in downtime.

Efficient cooling systems rely heavily on heat exchange technology. Enhanced heat transfer mechanisms, such as spiral and plate designs, double their efficiency compared to traditional models. These newer designs can handle varying flow rates more effectively, which is crucial for energy conservation. Data indicates that implementing these technologies can reduce energy consumption by up to 30%.

Tips: Consider regular inspections of material integrity. This ensures the cooling towers function optimally. Keep an eye on the maintenance schedules. Neglecting small issues may lead to bigger performance drops over time. Take time to evaluate new technologies continually. They could provide significant benefits, but not all innovations will fit every facility's needs.

Maintenance Practices for Optimal Cooling Tower Efficiency

Regular maintenance is crucial for cooling tower efficiency. Neglecting this aspect can lead to reduced performance and unnecessary energy costs. Routine inspections are important. Check for scale buildup or corrosion. Water quality should also be monitored closely. Maintaining proper pH levels prevents fouling and scaling.

Cleaning is another key practice. Sediment and debris can obstruct airflow and reduce cooling capacity. Inspect the fill media often. This part can become dirty quickly. It is essential to keep it clean. It's a tough job, but ignoring it leads to more significant issues later.

Also, monitor fan operation. Unusual sounds or vibrations signal that something is wrong. Inspecting bearings and belts regularly can prevent more extensive repairs. Ensure that all components are in good condition. A small oversight today could cause expensive downtime tomorrow. Balancing performance and maintenance is an ongoing challenge. It requires diligence and regular effort.